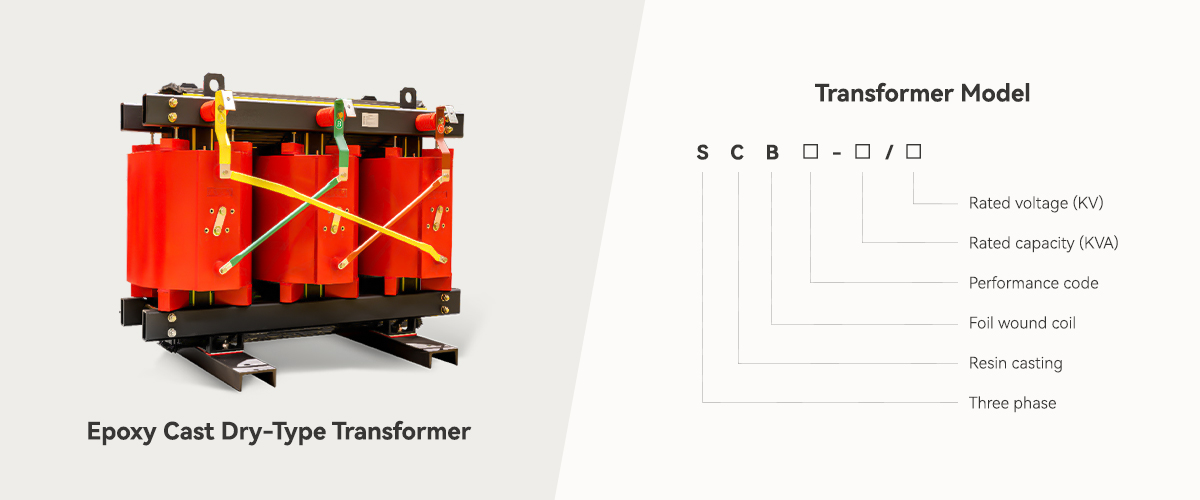

Design, Equipment, and Manufacturing Process of SC(B) Series Dry-Type Transformers

Design: Based on more than 30 years of design, manufacturing, and experimental experience in the transformer industry, CEEG has developed a set of advanced "three-dimensional + parametric" design software, that can realize automatic design, cost optimization, and simulation. Fully considering the requirements of the national and industrial standards, ensuring the advanced design of products.

High Voltage Coil Semi-Finished Products: The high-voltage winding conductor is meticulously crafted using high-quality materials and reinforced with long and short-cut fiberglass mats. It is cast within a vacuum using the world's most advanced Heidrich vacuum casting system. This process effectively suppresses the occurrence of partial discharge, with partial discharge levels ≤ 5PC.

Low Voltage Coil Semi-Finished Products: The low-voltage winding adopts a high-quality foil conductor and is wound on an automatic foil winding machine. This winding machine utilizes patented technology for "foil wire hydraulic energy-saving tension coiling devices," ±0.5mm high-precision detection, and advanced argon arc welding techniques, all of which play a critical role in ensuring the quality of coil winding.

Iron Core: The iron core is crafted from high-quality, highly permeable oriented silicon steel sheets using a 45 ° full oblique step lapping process. Its surface is coated with a special moisture-resistant and rust-resistant coating, effectively reducing no-load loss, no-load current, and noise levels.

Advanced Testing and Inspection Facilities: All products strictly control the production process and quality links, and conduct strict tests and inspections according to national standards and customer-customized requirements before leaving the factory, including partial discharge inspection, lightning resistance and electric shock inspection, noise inspection, and other necessary inspection items. Advanced test and detection equipment and perfect inspection and detection system ensure the high quality and high quality of products.

Our production base covers an area of more than 600 acres (40 hectares) with extensive facilities and a total construction area of 180,000 square meters. We have a professional team of more than 1,000 employees. We have advanced transformer production and testing equipment here to ensure that we provide customers with high-quality power transformer products.

We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane. We adopt the latest technology and processes to ensure that our products comply with international standards and customer needs.

We have a strong production capacity of 30 million kVA power transformers per year. This means we can cater to all sizes and types of power transformer needs, from small applications to large energy projects. No matter what specifications our customers require, we deliver them on time and support them with high quality and reliability.

Welcome to the CEEG agent team! As a national high-tech enterprise specializing in researching, developing, and manufacturing amorphous alloy dry-type transformers, epoxy resin cast dry-type transformers, and explosion-proof electrical products, we sincerely invite you to collaborate with us to explore markets and create the future together.

By joining our agent team, you will enjoy the following advantages and support:

Quality Products: Our products are manufactured with internationally advanced technology and quality assurance, widely used in various industries, providing customers with stable and efficient solutions for power transmission.

Brand Support: As an agent of CEEG, you will receive strong brand support and marketing promotion from us, helping you establish a good reputation and position in the local market.

Technical Support: We will provide professional product training and technical support to distributors, helping you better understand product characteristics and application scenarios, and improve sales capabilities.

Generous Returns: We will provide agents with competitive pricing policies and sales commissions, sharing market achievements.

If you are interested in becoming an agent of CEEG, don't hesitate to contact our official number +86 18061639839, or email us at info@ceegelectric.com to obtain an agency agreement. We look forward to cooperating with you and jointly creating a bright future!