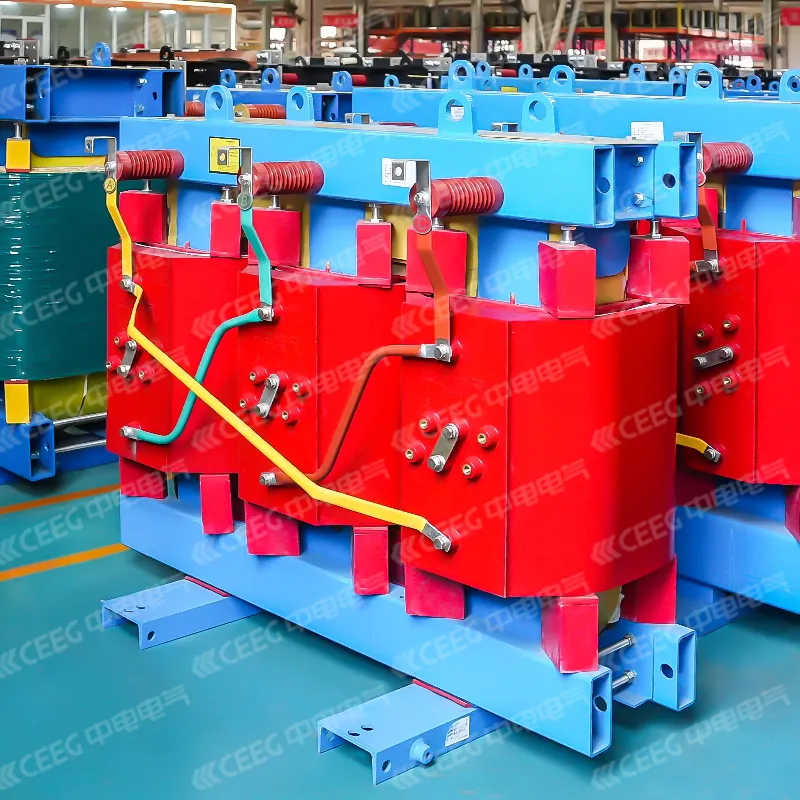

Amorphous alloy transformers, which emerged in the 1970s, represent a novel category of electrical transformers that utilize amorphous alloys instead of silicon steel as core materials. They offer a substantial reduction of approximately 70%-80% in no-load losses compared to transformers with silicon steel cores, along with a decrease of approximately 85% in no-load current. These transformers are currently among the most energy-efficient options available, making them well-suited for distribution applications with lower utilization rates and stringent safety requirements, such as rural power grids, high-rise buildings, commercial centers, subways, airports, stations, industrial and mining enterprises, as well as power plants.

Key Performance Features:

1. The core material is made of amorphous alloys that exhibit 70%-80% lower iron losses compared to conventional products.

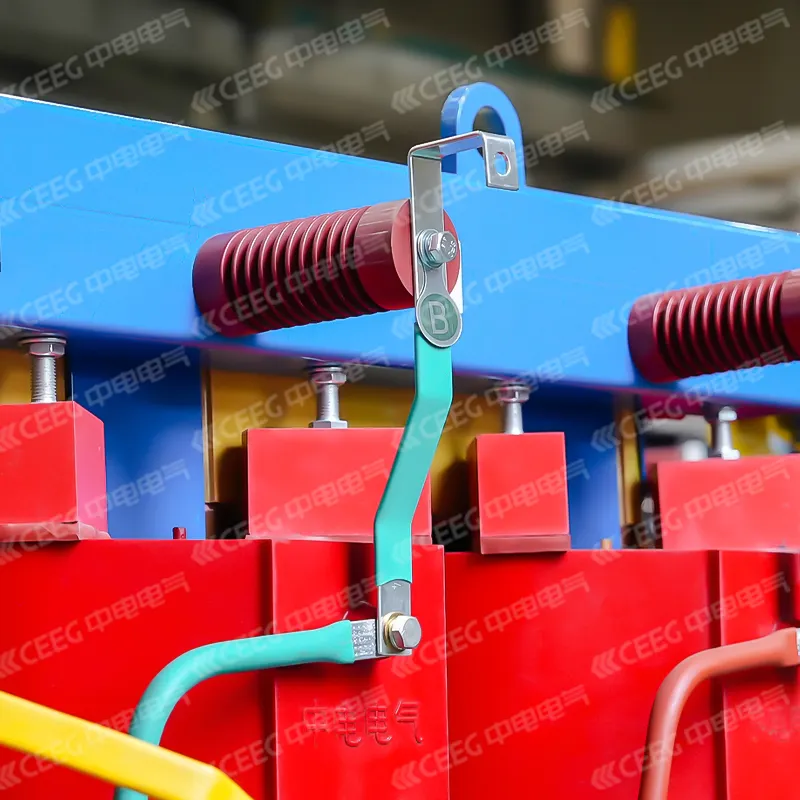

2. The core's design is simple yet robust, with a unique manufacturing process that imparts high mechanical strength, ensuring resistance to transportation and vibration-induced damage.

3. The amorphous alloy's distinctive three-phase three-column structure ensures a uniform magnetic path and outstanding performance, offering the flexibility of Dyn11 or Yyn0 connections.

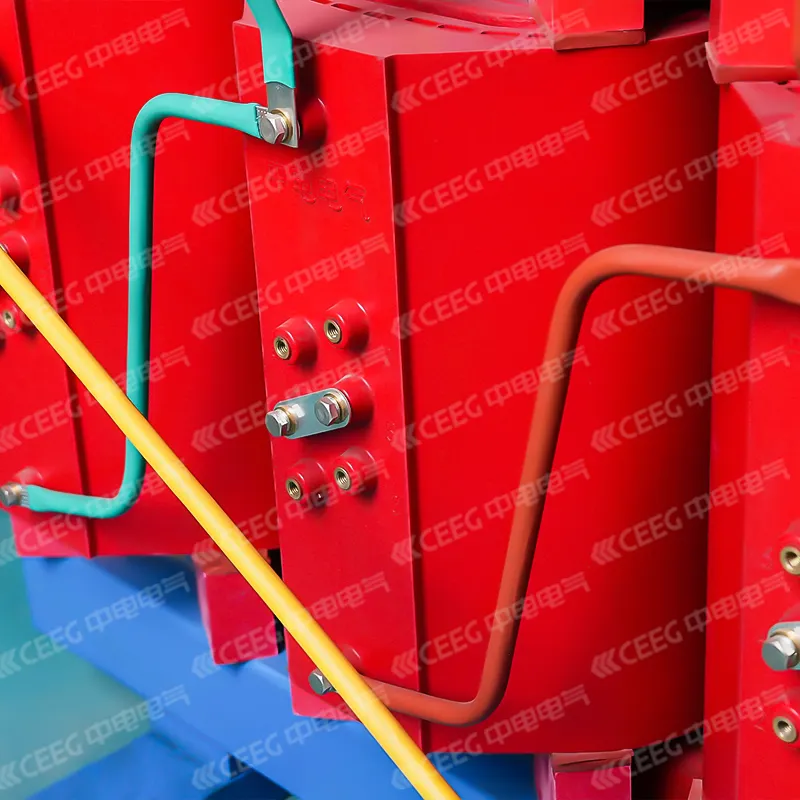

4. The coil exhibits high mechanical strength and strong short-circuit resistance.

5. Employing high-temperature-resistant insulation materials and a longitudinal multi-channel design enhances the coil's resistance to thermal shocks, significantly extending the product lifespan.

6. Distinguished from conventional epoxy-cast dry-type transformers, these transformers are characterized by their energy efficiency, environmental friendliness, and recyclability.

Our transformer production facility covers an area of over 40 hectares with a construction area of 180,000 square meters. It employs more than 1000 people and is equipped with a complete set of advanced transformer production and testing equipment, including cutting, vacuum casting, vacuum impregnation, and other facilities. It has an annual production capacity of 30 million kVA for power transformers. We boast an array of cutting-edge equipment representing a high standard within the industry, including a complete set of shearing machines, fully automated winding machines, robot-operated stacking machines, the Hedrch Hedrch Vacuum Casting Equipment, vacuum impregnation systems, air cushion transport vehicles, a fully enclosed production workshop with a cleanliness level of 100,000, 20-ton vertical winding machines, 10-ton horizontal winding machines, coal-oil gas phase drying equipment, and a 200-ton overhead crane. We adopt the latest technology and processes to ensure our products comply with international standards and customer needs.